Analyse des applications de la technologie RFID dans l'industrie alimentaire

La technologie d'identification par radiofréquence (Radio Frequency Identification RFID) est une technologie d'identification automatique sans contact, qui identifie automatiquement les objets cibles et obtient des données pertinentes via des signaux de radiofréquence sans intervention manuelle. Par rapport aux technologies d'identification automatique traditionnelles telles que les codes à barres, les bandes magnétiques, les cartes magnétiques et les cartes à puce, la technologie RFID présente les avantages d'une automatisation élevée, d'une longue distance de reconnaissance, d'une grande quantité d'informations stockées et d'une forte adaptabilité environnementale. De plus, la technologie RFID a permis un fonctionnement passif et sans contact, une application pratique, aucune usure mécanique, une longue durée de vie, peut mieux garantir la sécurité de l'appareil, si vous êtes intéressé par ce produit ou souhaitez en savoir plus,

1 Technologie et principe RFID

Le système RFID doit avoir deux capacités clés, la première est l'identification automatique, la lecture des données et les capacités d'écriture ; la seconde concerne les capacités de traitement des données pouvant répondre au stockage et à la conversion des données. Le système général 3 RFID comprend les 3 composants de base suivants :

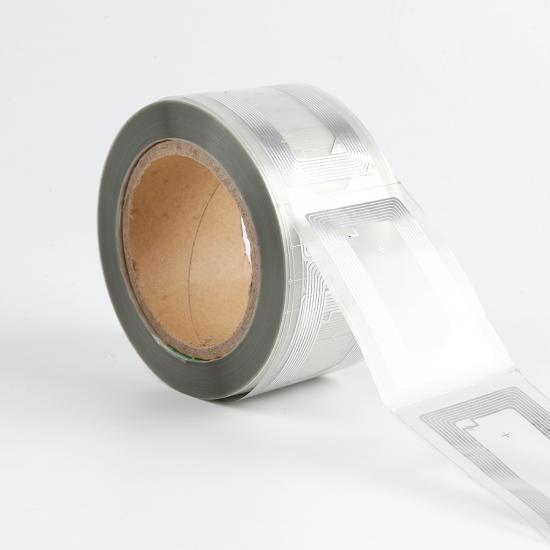

1.1 Etiquette électronique

Généralement composée de puces et de composants de couplage, la fonction principale est de compléter la communication avec le lecteur/enregistreur. Par rapport au code à barres, à la carte magnétique, à la carte à puce et à d'autres technologies d'identification précoce ou précoce, les cartes d'identification par radiofréquence présentent les avantages d'une longue distance de travail sans contact, adaptées aux environnements difficiles et de cibles mobiles reconnaissables.

Selon différentes méthodes d'alimentation en énergie, les étiquettes RFID peuvent être divisées en étiquettes passives, étiquettes semi-actives et étiquettes actives. L'énergie des puces des étiquettes semi-actives et des étiquettes actives est fournie par la batterie attachée à l'étiquette électronique. Les balises actives peuvent envoyer activement des signaux de radiofréquence. Selon les différentes fréquences de fonctionnement, les étiquettes RFID peuvent être divisées en micro-ondes, ultra haute fréquence (UFH), haute fréquence (HF) et basse fréquence (LF) et d'autres types différents. Le principe de fonctionnement de la RFID dans différentes bandes de fréquences est différent. La RFID de bande micro-ondes et ultra-haute fréquence adopte généralement le principe d'émission électromagnétique, et les étiquettes électroniques RFID de bande haute fréquence et basse fréquence adoptent généralement le principe de couplage électromagnétique.

1.2 Lecteur

Le lecteur est un appareil permettant de lire les informations des balises. Le lecteur RFID doit contrôler le module de radiofréquence pour transmettre un signal de lecture à l'étiquette et recevoir la réponse de l'étiquette, décoder les informations d'identification d'objet de l'étiquette et transmettre les informations d'identification d'objet ainsi que d'autres informations pertinentes sur l'étiquette à l'hôte pour traitement.

Dans la plupart des systèmes RFID, le lecteur émet des ondes électromagnétiques dans une zone (la taille de la zone dépend de la fréquence de fonctionnement et de la taille de l'antenne). Il y a un circuit de résonance série LC dans la carte, la fréquence est la même que la fréquence émise par le lecteur. Lorsque la carte radiofréquence traverse cette zone, sous l'excitation des ondes électromagnétiques, le circuit résonnant LC entre en résonance, de sorte qu'il y a une charge dans le condensateur. A l'autre extrémité de ce condensateur, une pompe électronique à canal unidirectionnel est connectée pour envoyer la charge dans le condensateur à un autre condensateur pour stockage. Lorsque la charge accumulée atteint 2V, ce condensateur peut être utilisé comme alimentation pour fournir une tension de fonctionnement à d'autres circuits, pour envoyer les données de la carte ou pour accéder aux données du lecteur. Une fois que le lecteur a reçu les données de la carte, il décode et effectue une vérification des erreurs pour déterminer la validité des données, puis transmet les données au réseau informatique via RS232, RS422, RS485 ou sans fil. Un produit RFID simple est une carte à puce sans contact, tandis qu'un produit RFID complexe peut être connecté à une interface de capteur externe pour mesurer et enregistrer différents paramètres, et peut même être connecté à un système GP S pour suivre des objets.

1.3 Système d'échange et de gestion des données

Le lecteur envoie une certaine fréquence de signaux radiofréquence. Lorsque la carte radiofréquence pénètre dans la zone de travail de l'antenne d'émission, un courant induit est généré. La carte radiofréquence obtient de l'énergie et est activée. La carte de radiofréquence envoie son propre code et d'autres informations via la carte intégrée. Le signal porteur envoyé par la carte est transmis au lecteur par l'intermédiaire du régulateur. Le lecteur démodule et décode le signal reçu, puis l'envoie au système principal d'arrière-plan pour un traitement associé. Le système principal juge la légalité de la carte en fonction de l'opération logique, effectue le traitement et le contrôle correspondants pour différents paramètres, émet des signaux de commande pour contrôler l'action de l'actionneur.

La technologie d'identification par radiofréquence utilise les caractéristiques de transmission des signaux de radiofréquence et le couplage spatial pour réaliser l'identification automatique des objets identifiés. Le système d'identification par radiofréquence est composé de trois parties : lecteur (lecteur, lecteur, lecteur), étiquette électronique (Tag) et système d'échange et de gestion des données. Le principe de la technologie d'identification par radiofréquence est le suivant : le lecteur génère un champ d'énergie dans la plage lisible pour stimuler l'étiquette électronique. Lorsque l'aliment avec l'étiquette électronique entre dans cette plage de distance, le lecteur contrôlera pour émettre un signal de requête micro-ondes, et après avoir reçu le signal du lecteur, l'étiquette électronique intègre le signal avec les informations de données dans l'étiquette et le renvoie à le lecteur. Le signal synthétisé par micro-ondes réfléchi transporte déjà les informations de données sur l'étiquette électronique. Le lecteur reçoit les micro-ondes réfléchies par le tag. Une fois le signal traité par le microprocesseur interne du lecteur, les informations stockées dans l'étiquette peuvent être lues.

2 Application de la technologie d'identification par radiofréquence dans les aliments

À mesure que la sensibilisation des gens à la salubrité des aliments s'est accrue, les ministères ont accordé plus d'attention à la salubrité des aliments et l'exposition des médias aux incidents de sécurité a rendu les problèmes de salubrité des aliments de plus en plus graves. La nourriture est directement liée à la santé des gens. En plus d'établir une série de normes nationales et industrielles pour réglementer la production, la transformation et la vente des aliments, des méthodes de haute technologie sont également nécessaires pour gérer la sécurité alimentaire. L'application de la technologie RFID à l'industrie alimentaire peut garantir efficacement la collecte d'informations en temps réel et avec précision, améliorer le niveau de gestion de la sécurité et de la surveillance des aliments, coordonner tous les aspects de la chaîne alimentaire, accroître la transparence de la compréhension des aliments par les gens et assurer la sécurité des aliments Ligne.

2.1 Application de la technologie RFID dans la lutte contre la contrefaçon alimentaire

En raison du système juridique imparfait actuel en Chine et du marché non réglementé, certains criminels nationaux et étrangers, pour faire des profits, ont spécialement contrefait des produits célèbres, les remplaçant par des produits de bonne qualité, formant un certain marché de produits contrefaits et inférieurs et perturbant gravement le social. ordre économique du marché La plupart des aliments contrefaits et de qualité inférieure sont des vins célèbres, des produits de santé et des produits spéciaux célèbres. Par rapport à d'autres technologies anti-contrefaçon telles que l'anti-contrefaçon numérique, l'anti-contrefaçon laser et d'autres technologies anti-contrefaçon, la RFID présente l'avantage que chaque étiquette possède un numéro d'identification unique au monde et ne peut être ni modifiée ni contrefaite ; pas d'usure mécanique et lecteur RFID anti-magnétique doté d'une interface physique qui n'est pas directement accessible à l'utilisateur final pour assurer sa propre sécurité ; il existe un processus d'authentification mutuelle entre le lecteur et l'étiquette ; et la RFID peut résister à des températures élevées et utiliser une longue durée de vie et une grande capacité de stockage ; les étiquettes sont facilement intégrées dans divers produits, ce qui peut augmenter considérablement la difficulté et le coût des contrefacteurs.

En Californie, aux États-Unis, la cave Sea Smoke Cellars a attaché des étiquettes RFID aux tonneaux de vin, puis a suivi les informations sur le vin pour empêcher la canalisation des marchandises.

Le Centre de recherche RFID de l'Institut d'automatisation de l'Académie chinoise des sciences a mis au point un système anti-contrefaçon RFID pour l'alcool. Le système se compose de bouchons et de bouteilles spécialement conçus, de réseaux de communication, de lecteurs RFID et de serveurs de base de données anti-contrefaçon.

2.2 La technologie RFID est utilisée pour le suivi et la traçabilité des aliments

Le concept de traçabilité défini dans la législation alimentaire générale de l'UE est : la capacité de tracer et de suivre les denrées alimentaires, les aliments pour animaux, les animaux destinés à l'alimentation ou les substances susceptibles d'être ajoutées aux denrées alimentaires ou aux aliments pour animaux à toutes les étapes de la production, de la transformation et de la commercialisation. Le système de traçabilité de la sécurité alimentaire consiste à utiliser une technologie moderne d'étiquetage informatif pour marquer efficacement chaque nœud de l'ensemble du processus de la chaîne d'approvisionnement alimentaire. La chaîne alimentaire, les matières premières, la transformation, l'emballage, le stockage, le transport, les ventes et les autres maillons de la chaîne d'approvisionnement assurent le contrôle de la qualité et le suivi et la traçabilité, le flux d'informations et la logistique physique sont systématiquement combinés. Une fois qu'un danger pour la santé est constaté, selon les informations qui doivent être enregistrées à toutes les étapes du processus de production et de vente, le sens du flux est suivi,Le suivi et la traçabilité des aliments sont la principale application de la technologie RFID dans l'industrie alimentaire. L'application de systèmes RFID peut garantir un échange de données de haute qualité dans la chaîne d'approvisionnement alimentaire, mettre en œuvre de manière approfondie des solutions de suivi des aliments « source » et fournir une transparence totale dans la chaîne d'approvisionnement alimentaire. Le système RFID peut assurer la connexion entre les aliments et les sources de la chaîne alimentaire afin d'assurer la clarté de la source alimentaire pour suivre des animaux ou des plantes et des fermes spécifiques, réalisant ainsi un suivi de la qualité et une traçabilité "de la terre agricole à la table".

Ces dernières années, il y a eu de nombreux incidents de sécurité alimentaire mettant en danger la santé humaine chez les animaux d'élevage, les volailles et leurs produits dans le monde, tels que l'"incident de la vache folle" au Royaume-Uni, l'"incident de la dioxine" en Belgique, l'"incident O157 épidémique épidémique" au Japon, et les incidents de la "fièvre aphteuse", ainsi que "l'incident du SRAS" en 2003 et "l'incident de la grippe aviaire" qui a touché de nombreux pays et régions en 2004. Une série de grands- les incidents de salubrité de la viande et des produits carnés à grande échelle ont entraîné des pertes considérables et de graves conséquences.

Le gouvernement américain exige que les bovins destinés à l'alimentation soient accompagnés d'étiquettes électroniques. En utilisant la technologie RFID pour suivre le bétail et la volaille afin d'obtenir le lien entre les aliments à base de viande et leur source animale dans la chaîne d'approvisionnement alimentaire, la source des aliments à base de viande peut être tracée pour atteindre l'objectif de fournir aux gens une alimentation sûre.

Le Bureau de surveillance et de coordination de la sécurité alimentaire de Pékin a proposé en 2006 d'utiliser des étiquettes d'oreille et des étiquettes de pied sur les produits animaux dans les bases d'élevage clés, et d'utiliser la technologie RFID dans l'abattage, la production et la circulation pour réaliser l'élevage, l'acquisition, l'abattage, la segmentation et la transport 3. Les informations sur les ventes sont enregistrées pour former un fichier de suivi pour un suivi facile.

Shanghai a mis en place un système de surveillance du porc basé sur la technologie RFID et a mis des étiquettes d'oreille électroniques à radiofréquence sur les oreilles de porc pour enregistrer l'alimentation des porcs, les dossiers médicaux, l'alimentation, le transfert de groupe, la quarantaine et d'autres informations. Utilisez des cartes RFID pour une supervision "point à point" avant d'entrer dans les grands passages urbains et les abattoirs pour vous assurer que les porcs entrent dans les abattoirs désignés. Sur le marché de gros, les étiquettes électroniques sont utilisées pour enregistrer l'origine du porc commercialisé, le temps de transaction et les résultats de l'inspection de sécurité des produits agricoles comestibles.

2.3 La technologie RFID est utilisée pour le contrôle de la qualité des aliments

Dans le traitement et le stockage des aliments, des facteurs tels que la température, l'humidité et le temps ont une grande influence sur la qualité des aliments. Il est très important d'enregistrer et d'analyser ces facteurs. Combinant la technologie RFID avec la technologie des capteurs, il peut détecter la température, l'humidité, la lumière et d'autres informations d'état des éléments environnants et de l'environnement, et peut utiliser la technologie de communication sans fil pour transmettre facilement ces informations d'état et leurs changements.

Fresh Alert a des capteurs de température intégrés et des minuteries dans les étiquettes RFID pour signaler quand les aliments sont pourris et non comestibles.

SYSCO, la plus grande organisation de marketing et de distribution de services alimentaires en Amérique du Nord, a terminé les tests de systèmes de radiofréquence et de capteurs pour les systèmes de stockage et de transport cryogéniques, montrant que la technologie RFID a la capacité de surveiller la température et les conditions environnementales pendant le transport des aliments.

Japan NTT Company a réalisé l'expérience d'utilisation de la technologie RFID pour maintenir la qualité du vin frais, en surveillant le changement de température pendant le transport pour saisir le changement de qualité du vin de riz.

2.4 La technologie RFID est utilisée pour la gestion de la logistique alimentaire

Afin de garantir que les aliments ne seront pas envoyés ou perdus par erreur lors du transport et de la circulation, ou pour réduire les coûts logistiques et améliorer l'efficacité du transport, l'ensemble du processus logistique doit être surveillé et géré. L'application de la technologie RFID au système de gestion de la logistique alimentaire peut faire jouer pleinement ses fonctions d'identification à longue distance et de traitement simultané multi-étiquettes, améliorant considérablement la capacité de tri des aliments, la vitesse et la précision du traitement, et réduisant le risque d'erreur de livraison ou de perte. D'énormes pertes. De plus, lors du suivi de matériaux importants ou de marchandises dangereuses, ou de la recherche d'un certain article parmi de nombreux articles, l'application de la technologie RFID peut également améliorer considérablement l'efficacité du travail.

Le groupe canadien d'entreposage frigorifique Atlas utilise largement les systèmes RFID dans sa chaîne du froid logistique alimentaire dans des environnements à basse température, ce qui non seulement réduit l'intensité du travail des travailleurs, mais améliore également considérablement l'efficacité et favorise l'intégration de l'entreposage frigorifique des aliments et de la gestion de la chaîne du froid.

L'australien Moraitis a remplacé le code-barres par son système RFID pour gérer le transport et la vente de ses tomates hydroponiques. Le système peut fournir à l'entreprise des données précises, notamment l'heure d'emballage, le lieu, la date d'emballage, la qualité, la catégorie et la taille.

Au cours des cinq dernières années, les sociétés cotées à Shanghai Wufeng ont mis en service l'abattage RFID et la mise en œuvre du système de surveillance et de gestion de la production pour marquer et charger les données relatives aux porcs, et réaliser la collecte de données et la gestion des informations de l'ensemble du processus d'abattage et production, afin que les responsables de la production puissent saisir et comprendre à temps la production et l'état de la qualité des produits.

2.5 Application de la technologie RFID à d'autres aspects

De plus, la technologie RFID peut être utilisée pour le contrôle des objets de traitement et des stations de traitement afin d'assurer le contrôle précis de la formulation précise du produit et d'améliorer la qualité du produit ; La technologie RFID peut également identifier rapidement la cause de la défaillance du produit et améliorer la qualité du produit en temps opportun ; La technologie RFID peut également être utilisée dans l'industrie de l'alimentation, elle peut être utilisée pour identifier les animaux, enregistrer et contrôler la peste, etc. par l'oesophage. information.

3 perspectives de la technologie RFID

La technologie RFID se développe rapidement au pays et à l'étranger. Il peut être appliqué à plusieurs liens dans le domaine alimentaire, ce qui peut garantir la sécurité des aliments, contrôler efficacement l'épidémie de maladies d'origine alimentaire, exclure certaines restrictions des lois et réglementations chinoises en matière d'importation et d'exportation de produits alimentaires. Le développement du l'industrie du produit fournit une garantie technique. La RFID est une technologie en plein essor avec un énorme potentiel de marché. La technologie et l'application d'identification par radiofréquence de la Chine en sont encore au stade initial de développement, mais à mesure que la technologie s'améliore et que les coûts et les prix baissent, son potentiel de développement est énorme et la perspective est également très attrayante.

![]()